Location: Canouan, Grenadines

Capacity: 160,000 USGPD (606 m3/d)

Description: 2x 80,000 USGPD seawater reverse osmosis trains

Commissioning Date: Temporary install on May 13th, 2016. To be relocated.

Delivery: 65 business days

Project Overview

ISI Water provided two containerized SWRO systems for a Caribbean marina in the spring of 2016. The product water is used for the marina, construction (concrete mixing), and for drinking by the construction crews, offices, and even local businesses.

Intake and Pretreatment

The plant draws water from an open sea intake where it is pumped through an automatic screen by Forsta, then through four fiberglass pressurized multimedia filters by Waterco, and finally a 5 micron cartridge filter constructed from Duplex 2205 by Fil-Trek. The entire pretreatment system is fully automated and can run unattended until the 5 micron cartridges need to be changed.

The Seawater RO System

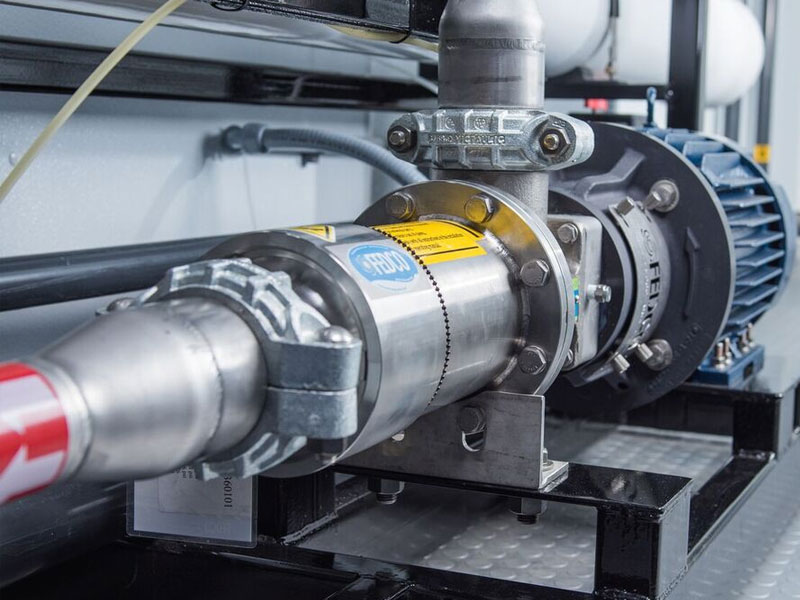

The SWRO systems were built for high efficiency and ease of operation. This plant was carefully designed to be simplistic without sacrificing performance or operational flexibility. The skids feature Danfoss APP high pressure pumps, Isobarix XPR 409SM pressure exchangers, FEDCO MSS boost pumps, Danfoss Aquadrive Nema 4 VFDs, and Protec pressure vessels. Each RO system produces 80,000 US gallons per day (303 m3/d) at an incredibly low energy consumption of 8.58 KWh per thousand US gallons (2.26 KWh/m3) including the intake system loads.

After RO, the product is run through a calcite remineralization system and dosed with chlorine. The entire plant is automated by an OPTO22 control system designed built and programmed by ISI Water.

The containers for the RO systems were furnished with stud walls, insulation, white FRP panelling with white PVC trim, industrial vinyl flooring, air conditioners and man doors with panic bars.